Purchasing laboratory equipment can be a difficult task. Especially when there are interchangeable terms of products; laminar flow, clean bench, fume hood, laminar flow hood. After a few minutes of browsing the internet, the lines begin to blur and things become less clear. So, what exactly is laminar flow? What is a fume hood? What is a laminar flow hood? Most importantly, how can your team make sure you are getting the right product to meet your needs? What is laminar flow?

Laminar flow is the linear movement of a fluid or gas in a smooth, or disturbance-free, path. Picture water exiting a faucet; it flows in a uniform line without disturbance. When the water hits the sink and washes around in multiple directions before draining, it becomes a turbulent flow. The water is still moving towards the drain, but the path is no longer uniformly moving linearly.

Primary engineering controls (PEC's), like horizontal laminar flow, clean benches, fume hoods, and biological safety cabinets. PEC's aim to provide laminar airflow dynamics. The laminar airflow prevents dead spots or areas with eddy currents, spaces where the air travels in a circular motion without exiting the unit. Looking at the differences between the variety of primary engineering controls on the market, we can begin to see why dead spots can be a problem. A dead-spot, or area within the engineering control that does not exhibit either positive or negative airflow, can lead to loss of containment or reduced cleanliness.

What is a fume hood?

PEC's are enclosures that manipulate air in a laminar flow manner to serve a purpose within your lab. Specifically, a fume hood is a PEC designed to capture and contain chemical fumes and vapors. According to OSHA 29 CFR 1910. 1450, a laboratory fume hood is an enclosure with five sides and an adjustable sixth side for operator interaction. The fume hood has a range of performance criteria depending on the application or experiment conducted inside the hood. At AirClean Systems, we try to break down the categories of laminar flow hoods: Operator Protection or Process Protection, depending on the customer and application requirements.

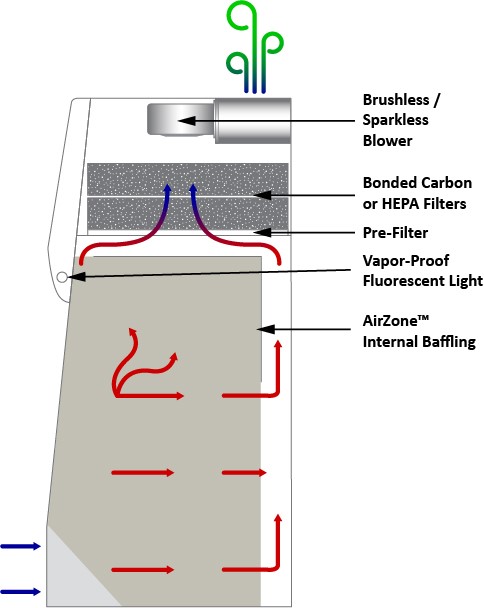

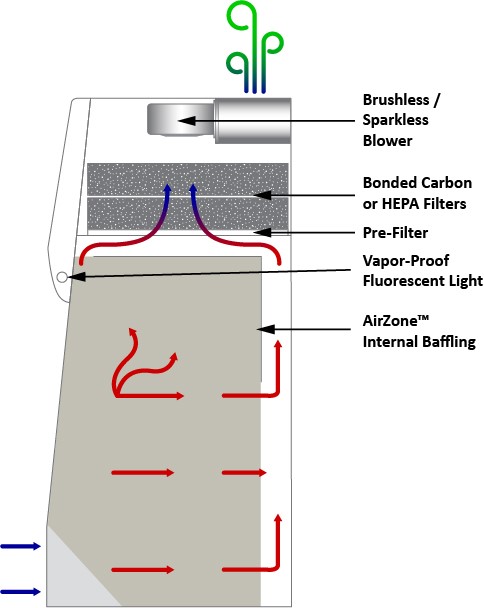

Operator protection fume hoods and laminar flow hoods classify as units designed to protect the end-user. This can be, for example, biological samples in the case of the biological safety workstation. It can also be hazardous fumes or vapors in the case of ductless or total exhaust fume hoods. These hoods pull air through the front sash and use a pressurized baffle system to provide laminar airflow dynamics. The engineered design of a fume hood should avoid any dead zones within the enclosure, and pull harmful fumes away from the end-user.

AirClean® Systems Ductless Fume Hoods employ AirZone™ Internal Baffling. The Fume Hoods are specifically designed to eliminate dead spots and maintain turbulence-free air throughout the unit. The AirZone baffling draws laboratory air into the front of the hood, creating an even laminar flow pattern, to the rear. This process eliminates dead zones or eddy currents. The laminar flow action prevents the buildup of potentially hazardous or contaminated air in the fume hood chamber. Buildup air can be a fire hazard or dangerous to the end-user. While this airflow would constitute laminar flow, this is not a traditional laminar flow hood as defined by various standards bodies.

What is a laminar flow hood?

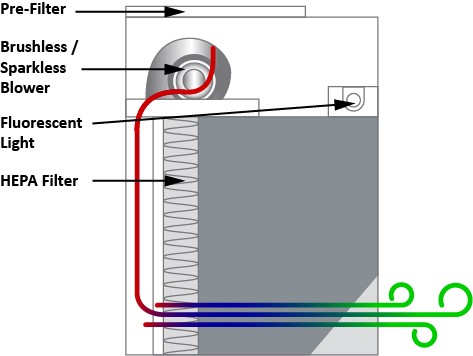

A laminar flow hood is defined as; an enclosed workbench used to create a contamination-free work environment through installed HEPA filters that capture all the particles entering the cabinet. A laminar flow hood is for working with substances that are not hazardous to the health of personnel. AirClean Systems' laminar flow hoods are categorized under our process protection line. Process protection describes hoods, workstations, and enclosures that protect samples from cross-contamination. These units force high-efficiency, particulate-free air (HEPA) over or across the work surface, in a laminar flow fashion. The design provides a clean, positive pressure environment that protects samples.

AirClean Systems' laminar flow hoods and clean benches create a low particulate ISO 5, Class 100 cleanroom environment perfect for applications like cell culture, and the preparation and handling of nucleic acids. Horizontal or vertical laminar airflow prevents dead spots that can harbor contamination within the unit and ultimately create the desired cleanroom environment required for the application.

What is a laminar flow fume hood?

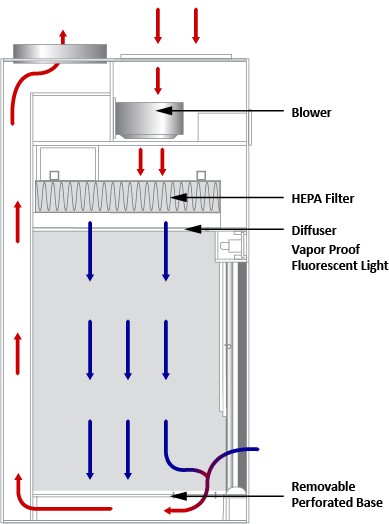

A laminar flow fume hood partners both the technology of process protection and operator protection within one unit. AirClean Systems DuraMax™ Total Exhaust Laminar Flow Hood offers this level of complete protection.

Clean ISO 5, Class 100 air is forced down over the work surface providing a clean working environment free of contamination. Laboratory air is then pulled in at the front of the unit while HEPA filtered air is forced down the front sash that creating an air curtain at the opening of the unit. This activity is designed to prevent contaminated air from entering the work surface. Air is then exhausted outside of the lab. The DuraMax is constructed from thermally fused polypropylene that offers an ideal solution for applications like trace metal analysis.

For more information on which laminar flow hood is right for your laboratory or a specific application, please contact AirClean Systems at +1 (919) 255-3220 or toll-free at (800) 849-0472. Alternatively, visit our website at www.aircleansystems.com and complete the application worksheet. One of our application specialists will contact you. Our knowledgeable staff will review the application and work with you to develop the right safety solution for you, your lab, and your staff.