A ductless solution for most common applications

-

Categories:

- Ductless Fume Hoods

- Operator Protection

Request Quote

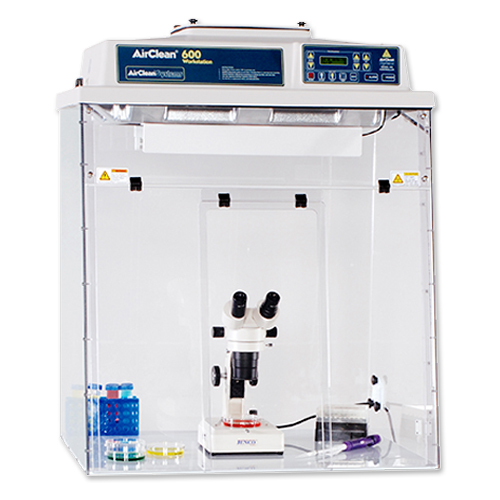

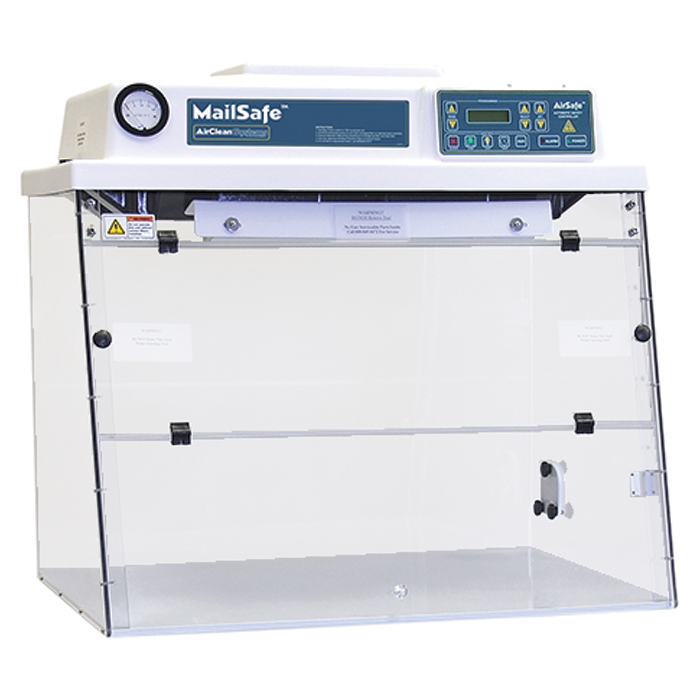

Application WorksheetPolypropylene ductless fume hoods protect both the operator and the environment by filtering toxic fumes, vapors, or gases through AirClean® Systems’ proprietary bonded carbon filtration. Standard with a thermally-fused integral spill tray, polypropylene ductless fume hoods are chemically resistant to virtually all corrosive applications.

For the widest application range possible, each polypropylene hood is designed to accommodate up to seven inches of filtration. By stacking a HEPA filter followed by a bonded carbon filter, the operator can effectively filter both toxic particulate and chemical fumes. For high evaporation or multi-chemical applications, a full seven-inch stack of chemical filtration may be recommended.